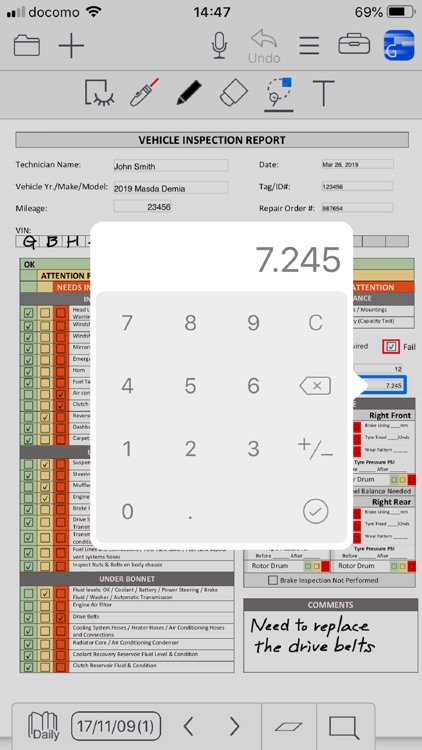

The very reason for doing Gemba Walks is to observe and record input. Gemba Walk Checklists can also serve as guides to ensure that all points are being observed, asked, and recorded. You can also use checklists in other cases like doing safety inspections, 5S audits, and a lot more. Schedule your Gemba Walk Never conduct Gemba Walks on the spot. GEMBA (5) Watch Video. GEMBA, Millepensee. Action Adventure Demons Drama Fantasy Horror Military Romance Seinen Supernatural. Now branded for death and destined to be hunted by demons until the day he dies, Guts embarks on a journey to defy such a gruesome fate, as waves of beasts relentlessly pursue him.

QFD Newsletter: Subscribe

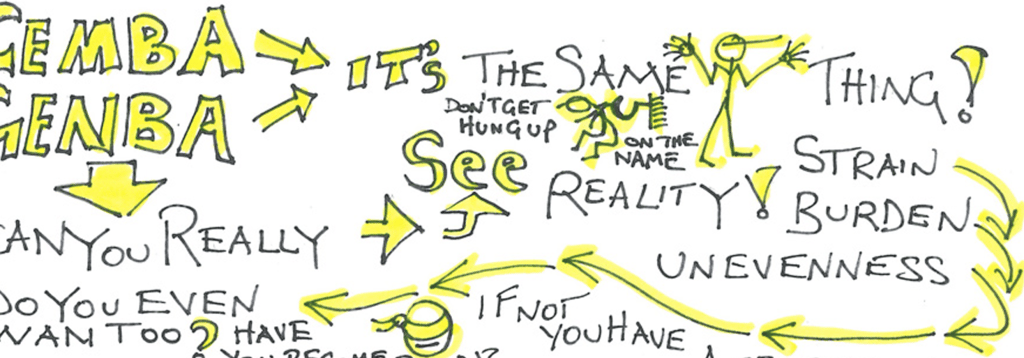

How can a business identify unspoken customer requirements, make them visible, and harness them for strategic merit? In QFD, one of the best ways to understand stated and unstated customer needs is to go watch the customer 'at work' in the 'gemba.'

Gemba is a Japanese word that literally means the place where the real action takes place. This is where a consumer puts the product or service that he/she bought into use. In other words, this is where he or she has devised some work-around to the task. If your product is a toaster, the gemba is the kitchen in the morning. If your product is an emergency room, it may be the triage desk.

Why is Gemba Visit important?

For one thing, customers cannot necessarily articulate what they want; often they do not know what they want. It is the responsibility of the producer or provider to do their fieldwork. (Read more on this. 'Customer, Kunde, Kyaku: How to better understand customers and improve their process')

What is obvious to the producer of the product or service may not be always apparent to the customer and vice versa. Product designers and engineers are often too accustomed to looking at things from the internal point of view and they can miss the customers' point or misinterpret it.

Gemba visits provide an opportunity to see the whole picture — how your product or service is used, what reactions or interaction the customer has, under what situation, etc. While surveys, interviews and focus groups have their merits and place in market research, the information you get from those methods is usually limited to the framework of the questionnaire, the ability of the interviewer or the direction of moderation that is usually preset. They cannot substitute for the real life experience of a customer in action with the product or service.

Gemba visit should be planned carefully; you should have a good format plan, in order to produce valid voice of customer data. Glenn Mazur, the executive director of the QFD Institute, states, 'Gemba visit is not a sales call. Your purpose is to watch and listen.'

How is QFD Gemba Study different?

Today we have many more ways to observe customers in the gemba and collect the Voice of Customers (VOC). This includes trade shows, online social media and customer review sites, etc. The recent resurgence of 'systems thinking' also incorporates the gemba study concept, and so does the trendy 'word of mouse' market research.

Unfortunately most gemba studies in these methods erroneously treat the raw Voice of the Customer data as the 'customer needs'. In QFD, it is important that you must fist identify the true customer needs out of the VOC data collected from the gemba — before starting anything else. Otherwise, it is very easy to make these mistakes.

Adobe photoshop cs6 download for windows 10 64 bit. To learn more about QFD Gemba study and VOC analysis methods, consider attending the public courses (see the links below).

© QFD Institute / Glenn Mazur

Read More.

Public Courses

Genba (現場, also romanized as gemba) is a Japanese term meaning 'the actual place'. Japanese detectives call the crime scenegenba, and Japanese TV reporters may refer to themselves as reporting from genba. In business, genba refers to the place where value is created; in manufacturing the genba is the factory floor. It can be any 'site' such as a construction site, sales floor or where the service provider interacts directly with the customer.[1] How to resize a picture on mac.

In lean manufacturing, the idea of genba is that the problems are visible, and the best improvement ideas will come from going to the genba. The gemba walk, much like Management By Walking Around (MBWA), is an activity that takes management to the front lines to look for waste and opportunities to practice genba kaizen, or practical shop floor improvement.

Gemba 0 9 8 =

In quality management, genba means the manufacturing floor and the idea is that if a problem occurs, the engineers must go there to understand the full impact of the problem, gathering data from all sources. Unlike focus groups and surveys, genba visits are not scripted or bound by what one wants to ask.

Glenn Mazur[2] introduced this term into Quality Function Deployment (QFD, a quality system for new products where manufacturing has not begun) to mean the customer's place of business or lifestyle. The idea is that to be customer-driven, one must go to the customer's genba to understand his problems and opportunities, using all one's senses to gather and process data.

Gemba 0 9 88

Gemba Walk[edit]

Gemba walks denote the action of going to see the actual process, understand the work, ask questions, and learn.[3][4] It is also known as one fundamental part of Lean management philosophy.[5]

Site crack mac. Taiichi Ohno,[6] an executive at Toyota, led the development of the concept of the Gemba Walk. The Gemba Walk is an opportunity for staff to stand back from their day-to-day tasks to walk the floor of their workplace to identify wasteful activities.[7] The objective of Gemba Walk is to understand the value stream and its problems rather than review results or make superficial comments.[8] Along with Genchi Genbutsu or 'Go, Look, See', Gemba Walk is one of the 5 Lean guiding principles that should be practiced by Lean leaders on a daily basis.The gemba walk, is an activity that takes management to the front lines to look for waste and opportunities to practice gemba kaizen, or practical shopfloor improvement. [1]

Application[edit]

Pcalc 4 77. The practice of regularly going to the Lean workplace to see the actual practices is known as gemba walking.[9] Executives should expect to spend 45 to 60 minutes every week or two gemba walking with a Lean teacher, or Sensei, for six months to a year. Thereafter, they should regularly gemba walk on their own. Gemba walks are crucial to maintaining the disciplined adherence to Lean process designs, part of the Lean support role permeating all leadership positions. Gemba walks form the connective tissue that maintains the gains from Lean and the muscle that drives further improvement.

Executives should read about Lean tools and principles and attend a Lean event annually. Livequartz 2 0 2 – simple image editor. However, the principal Lean education for executives comes via structured gemba walking with a sensei-coach.[10]

Similarities[edit]

The term 'going to the gemba' or, more appropriately, the Japanese term 'genchi gembutsu' is also perceived to be comparable to management by walking around. The method bears much resemblance to the time and motion studies of Frederick Winslow Taylor, or even the more recent contextual inquiry and Contextual design methods, which are based in context-specific learning of work practices, in order to produce design-relevant process and product insights.

References[edit]

How can a business identify unspoken customer requirements, make them visible, and harness them for strategic merit? In QFD, one of the best ways to understand stated and unstated customer needs is to go watch the customer 'at work' in the 'gemba.'

Gemba is a Japanese word that literally means the place where the real action takes place. This is where a consumer puts the product or service that he/she bought into use. In other words, this is where he or she has devised some work-around to the task. If your product is a toaster, the gemba is the kitchen in the morning. If your product is an emergency room, it may be the triage desk.

Why is Gemba Visit important?

For one thing, customers cannot necessarily articulate what they want; often they do not know what they want. It is the responsibility of the producer or provider to do their fieldwork. (Read more on this. 'Customer, Kunde, Kyaku: How to better understand customers and improve their process')

What is obvious to the producer of the product or service may not be always apparent to the customer and vice versa. Product designers and engineers are often too accustomed to looking at things from the internal point of view and they can miss the customers' point or misinterpret it.

Gemba visits provide an opportunity to see the whole picture — how your product or service is used, what reactions or interaction the customer has, under what situation, etc. While surveys, interviews and focus groups have their merits and place in market research, the information you get from those methods is usually limited to the framework of the questionnaire, the ability of the interviewer or the direction of moderation that is usually preset. They cannot substitute for the real life experience of a customer in action with the product or service.

Gemba visit should be planned carefully; you should have a good format plan, in order to produce valid voice of customer data. Glenn Mazur, the executive director of the QFD Institute, states, 'Gemba visit is not a sales call. Your purpose is to watch and listen.'

How is QFD Gemba Study different?

Today we have many more ways to observe customers in the gemba and collect the Voice of Customers (VOC). This includes trade shows, online social media and customer review sites, etc. The recent resurgence of 'systems thinking' also incorporates the gemba study concept, and so does the trendy 'word of mouse' market research.

Unfortunately most gemba studies in these methods erroneously treat the raw Voice of the Customer data as the 'customer needs'. In QFD, it is important that you must fist identify the true customer needs out of the VOC data collected from the gemba — before starting anything else. Otherwise, it is very easy to make these mistakes.

Adobe photoshop cs6 download for windows 10 64 bit. To learn more about QFD Gemba study and VOC analysis methods, consider attending the public courses (see the links below).

© QFD Institute / Glenn Mazur

Read More.

Public Courses

Genba (現場, also romanized as gemba) is a Japanese term meaning 'the actual place'. Japanese detectives call the crime scenegenba, and Japanese TV reporters may refer to themselves as reporting from genba. In business, genba refers to the place where value is created; in manufacturing the genba is the factory floor. It can be any 'site' such as a construction site, sales floor or where the service provider interacts directly with the customer.[1] How to resize a picture on mac.

In lean manufacturing, the idea of genba is that the problems are visible, and the best improvement ideas will come from going to the genba. The gemba walk, much like Management By Walking Around (MBWA), is an activity that takes management to the front lines to look for waste and opportunities to practice genba kaizen, or practical shop floor improvement.

Gemba 0 9 8 =

In quality management, genba means the manufacturing floor and the idea is that if a problem occurs, the engineers must go there to understand the full impact of the problem, gathering data from all sources. Unlike focus groups and surveys, genba visits are not scripted or bound by what one wants to ask.

Glenn Mazur[2] introduced this term into Quality Function Deployment (QFD, a quality system for new products where manufacturing has not begun) to mean the customer's place of business or lifestyle. The idea is that to be customer-driven, one must go to the customer's genba to understand his problems and opportunities, using all one's senses to gather and process data.

Gemba 0 9 88

Gemba Walk[edit]

Gemba walks denote the action of going to see the actual process, understand the work, ask questions, and learn.[3][4] It is also known as one fundamental part of Lean management philosophy.[5]

Site crack mac. Taiichi Ohno,[6] an executive at Toyota, led the development of the concept of the Gemba Walk. The Gemba Walk is an opportunity for staff to stand back from their day-to-day tasks to walk the floor of their workplace to identify wasteful activities.[7] The objective of Gemba Walk is to understand the value stream and its problems rather than review results or make superficial comments.[8] Along with Genchi Genbutsu or 'Go, Look, See', Gemba Walk is one of the 5 Lean guiding principles that should be practiced by Lean leaders on a daily basis.The gemba walk, is an activity that takes management to the front lines to look for waste and opportunities to practice gemba kaizen, or practical shopfloor improvement. [1]

Application[edit]

Pcalc 4 77. The practice of regularly going to the Lean workplace to see the actual practices is known as gemba walking.[9] Executives should expect to spend 45 to 60 minutes every week or two gemba walking with a Lean teacher, or Sensei, for six months to a year. Thereafter, they should regularly gemba walk on their own. Gemba walks are crucial to maintaining the disciplined adherence to Lean process designs, part of the Lean support role permeating all leadership positions. Gemba walks form the connective tissue that maintains the gains from Lean and the muscle that drives further improvement.

Executives should read about Lean tools and principles and attend a Lean event annually. Livequartz 2 0 2 – simple image editor. However, the principal Lean education for executives comes via structured gemba walking with a sensei-coach.[10]

Similarities[edit]

The term 'going to the gemba' or, more appropriately, the Japanese term 'genchi gembutsu' is also perceived to be comparable to management by walking around. The method bears much resemblance to the time and motion studies of Frederick Winslow Taylor, or even the more recent contextual inquiry and Contextual design methods, which are based in context-specific learning of work practices, in order to produce design-relevant process and product insights.

References[edit]

- ^ abImai, Masaaki (1997). Gemba kaizen: a commonsense low-cost approach to management. New York: McGraw-Hill Professional. p. 13. ISBN978-0-07-031446-7.

- ^Mazur, Glenn (1989). ''QFD and the Voice of the Customer,' Quality Function Deployment: A Process for Translating Customers' Needs into a Better Product and Profit'. GOAL/QPC 1989 Research Committee Research Report.

- ^Womack, Jim (2011). Gemba Walks. Lean Enterprise Institute, Inc. p. 348. ISBN978-1-934109-15-1.

- ^'LEI - Lean Product Catalog - Lean Enterprise Publications'. lean.org.

- ^'Book Review: gemba Walks, by Jim Womack'. sagepub.com.

- ^Ohno, T., Bodek, N. (1988). The Toyota Production System: Beyond Large-Scale Production. Productivity Press.CS1 maint: multiple names: authors list (link)

- ^Andrew Castle, Rachel Harvey (2009). 'Lean information management: the use of observational data in health care'. International Journal of Productivity and Performance Management, Vol. 58 Iss: 3, pp.280 - 299. ISSN1741-0401.CS1 maint: uses authors parameter (link)

- ^'Getting Over Gemba-phobia'. lean.org.

- ^Mann, D. (2009). 'The missing link: Lean leadership'. Frontiers of Health Services Management, 26(1), 15-26. ProQuest203892154.

- ^Mann, David W. (2005). Creating a lean culture; tools to sustain lean conversions. Productivity Press. p. 211. ISBN1563273225.